If you are seeking for high-end ingredients tracking solution, welcome to contact us!

With increasingly stringent requirements for temperature-controlled logistics in global food, pharmaceutical, and chemical industries, coupled with growing consumer attention to food safety and drug expiration dates, the market demand for cold chain transportation monitoring equipment is showing steady growth. Against this backdrop, enhancing end-to-end data traceability has become an industry necessity.

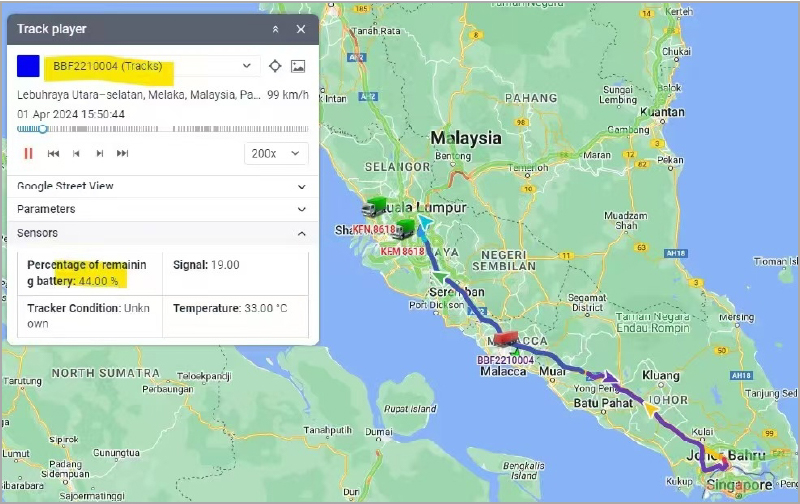

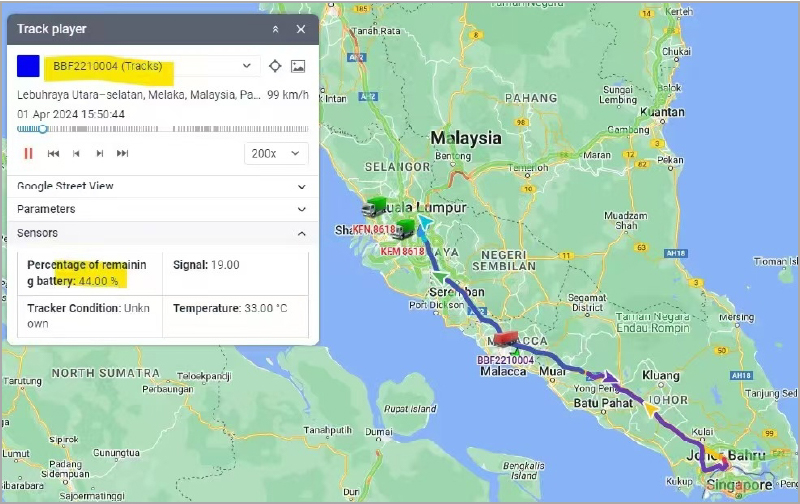

Glob is a professional cold chain logistics management company in Malaysia, specializing in temperature-controlled logistics services for seafood, fruits, and other fresh ingredients. In 2023, to meet customers' stringent requirements for durian export and transportation, Glob needed to achieve comprehensive visual management and real-time monitoring throughout the entire process. This addresses risks of accidental cargo damage during transportation, ensures compliance with temperature and humidity environment requirements throughout the journey, and guarantees standardized delivery of food quality. To this end, Glob adopted Think Power's Tiger Mini (integrated with positioning, temperature/humidity sensors, light sensors, and G-sensors) combined with its self-developed software service platform to build an end-to-end cold chain monitoring solution.

This intelligent monitoring solution establishes three core functional systems covering the entire durian supply chain process:

1. End-to-end Traceability & Data Collection

Starting from the production origin, the system automatically collects and records product traceability information. Through multiple sensors, it continuously monitors key parameters including temperature, humidity, and location coordinates during transportation, ensuring complete and traceable data throughout the entire journey.

2. Intelligent Risk Alert

The system identifies abnormal conditions during transportation in real time, including temperature/humidity exceedances, route deviations, unauthorized openings, and severe vibrations. It triggers alerts to enable minute-level response.

3. Data-driven Decision Support

The visualization platform displays real-time transportation status, allowing teams to not only quickly activate emergency plans but also build analytical models based on historical transportation data. This provides data support for transportation optimization management decisions, enabling continuous improvement of transportation efficiency.

Stable operation at -20°C to 60°C. Ultra-low power design, sustainable operation for more than 35 days.

2)High-precision sensor:

Record small changes in temperature and humidity, light changes, and motion state changes.

3)Real-time alarm:

Temperature and humidity overlimit alarm, light change, movement and static, impact, fall real-time alarm.

4)Flexible control:

It can flexibly set the parameter: position reporting period, temperature and humidity sampling period, temperature and humidity alarm interval, light sense on/off, G-sensor sensitivity, etc.

5)Continuous operation:

By unplugging the "Pull tab", that is, the design mode of startup and "can not be turned off", to ensure the continuous operation of the device.

6)Cost-effective design:

The functional design of the device and the data management platform is highly flexible, and the TL-904M can be used as a single-use product or recycled. The data management platform can be flexibly customized and presented according to customer requirements.

Use Case: Truck Fleet and Personnel Management Solution

Use Case: Truck Fleet and Personnel Management Solution

Use Case: Bus Fleet and Personnel Management Solution

Use Case: Bus Fleet and Personnel Management Solution

Use Case: Forklift Operation Management Solution

Use Case: Forklift Operation Management Solution

Use Case: Tractor-trailer tracking across the U.S.-Mexico border

Use Case: Tractor-trailer tracking across the U.S.-Mexico border